What Advice is Crucial for Conducting Effective Electrical Inspections?

When it comes to performing effective electrical inspections on complex systems, the advice of an experienced Electrician is invaluable, emphasizing the need to follow a systematic inspection approach. Alongside this expert insight, we've gathered additional answers, ranging from safety practices to documentation protocols, to provide a well-rounded guide. From the crucial step of de-energizing circuits to the meticulous documentation of findings, here is a collection of essential tips for ensuring thorough and safe electrical inspections.

- Follow a Systematic Inspection Approach

- De-Energize Circuits for Safety

- Use Calibrated Testing Equipment

- Inspect Grounding and Bonding Systems

- Adhere to Updated Electrical Codes

- Document Findings Precisely

Follow a Systematic Inspection Approach

One crucial piece of advice for conducting effective electrical inspections on complex systems is to follow a systematic and comprehensive approach. Here are some key steps to ensure a thorough inspection:

Develop a Checklist:

Create a detailed checklist that covers all aspects of the electrical system, including components, connections, controls, and safety features.

Tailor the checklist to the specific complexities and intricacies of the system you are inspecting.

Understand System Design and Documentation:

Familiarize yourself with the electrical system's design and layout. Review schematics, wiring diagrams, and any relevant documentation to understand how different components are interconnected.

Pay attention to critical components, control panels, power distribution points, and safety features.

Prioritize Critical Components:

Identify critical components that are essential for the safe and efficient operation of the system. Focus on inspecting these components with extra scrutiny.

Prioritize inspection based on the impact of component failure on system performance.

Check for Compliance with Codes and Standards:

Ensure that the electrical system complies with relevant electrical codes, safety standards, and regulations.

Stay updated on the latest industry standards and incorporate them into your inspection

Process.

Inspect Wiring and Connections:

Examine all wiring and connections for signs of wear, damage, or overheating.

Tighten loose connections and replace damaged or worn-out wiring promptly.

Perform Functional Tests:

Conduct functional tests to ensure that all components operate as intended.

Test safety features, alarms, and emergency shutdown systems to verify their effectiveness.

Thermal Imaging and Infrared Scanning:

Use thermal imaging and infrared scanning to detect hotspots or abnormal heat patterns in electrical components. This can help identify potential issues before they lead to failures.

Consider Environmental Factors:

Take into account environmental conditions that may impact the electrical system, such as temperature, humidity, and exposure to corrosive substances.

Address any environmental issues that could affect the system's performance.

Documentation and Reporting:

Document your findings systematically, including any issues discovered, repairs made, and recommendations for future maintenance.

Provide a clear and concise report to relevant stakeholders, emphasizing safety concerns and critical areas requiring attention.

De-Energize Circuits for Safety

To ensure that electrical inspections are not only thorough but also adhere to safety protocols, it is essential to start with de-energizing any circuits that are to be inspected. This crucial step helps prevent electrical shocks and other potentially dangerous situations for the inspector and anyone else nearby. It lays the foundation for a secure environment where a detailed examination can take place without the risk of live current.

It is vital to remember that electricity can be lethal and respecting its power is the first rule of safe inspection practices. Before proceeding with any electrical inspection, make sure to turn off the power and lock out the circuits to create a safe inspection environment.

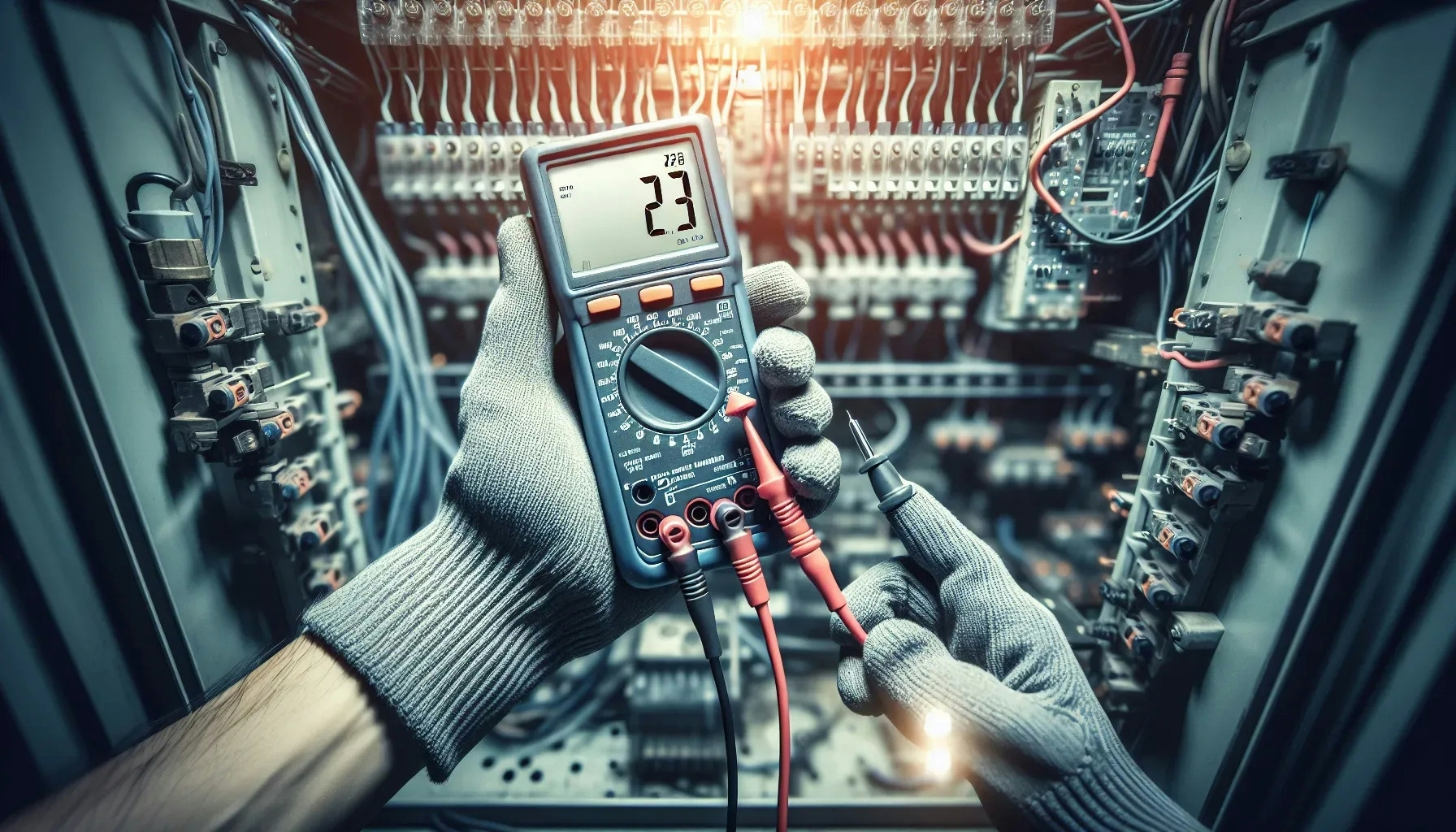

Use Calibrated Testing Equipment

Effective electrical inspections require the use of testing equipment that is current and has been properly calibrated to deliver accurate measurements. With technology constantly evolving, outdated devices might not detect newer electrical issues or may even give false readings, leading inspectors to overlook potentially serious electrical faults. Regular calibration ensures that the equipment provides precise data, essential for diagnosing electrical health and safety.

To achieve dependable results in electrical inspections, it is crucial to routinely check and maintain your testing instruments. Invest the time to keep your equipment up-to-date and well calibrated, ensuring your inspections are based on reliable information.

Inspect Grounding and Bonding Systems

Verifying the adequacy of grounding and bonding systems is a fundamental aspect of any electrical inspection. These systems are designed to ensure that in the event of a fault, electricity has a safe path to the earth, which significantly reduces the risk of electric shock or fire. An inspection that closely examines grounding and bonding can identify potential safety hazards, ensuring that they are addressed to protect against electrical malfunctions.

Without proper grounding, even the most advanced electrical systems can become dangerous. Therefore, it is imperative to scrutinize the grounding and bonding in each inspection thoroughly and ensure they meet safety standards.

Adhere to Updated Electrical Codes

Compliance with current electrical codes and standards is non-negotiable for conducting effective electrical inspections. These codes are frequently updated to reflect new knowledge, technologies, and safety practices in the electrical industry. Ignoring the latest codes could result in overlooking major safety issues which could lead to electrical failures or even disasters.

Adherence to these regulations is not only a matter of following the law but also a commitment to ensuring the highest level of safety. Remember to stay informed about the latest electrical codes and apply them diligently during every inspection.

Document Findings Precisely

The importance of documenting one's findings in a clear and accurate manner after an electrical inspection cannot be overstated. Precise documentation is valuable for maintaining a record of the inspection, noting any potential issues or areas that require attention, and providing a basis for future inspections or maintenance.

Such records can aid in tracking the condition of an electrical system over time and are critical components for accountability and continuous safety improvement. To uphold the highest standards of electrical inspection practices, always document your findings with clarity and precision for the benefit of current and future stakeholders.